Uncategorized

A SHIPPER’S GUIDE TO CARGO VESSEL TYPES & DIMENSIONS

Most of the world’s cargo is shipped via container vessels. They vary in their dimensions, which will influence through where they may or may not transit. That is not all: there are multiple other types of ships journeying across our planet’s oceans, all dedicated to specific commodities and cargo types. The Freight Forwarding Experts share a quick recap of the world of ships as it stands today.

A Little History of the Container Vessel

If you have read our article on container types and sizes, then you know that the first container vessel was actually a tanker vessel (find out more on these ships), the Ideal X, which journeyed from New Ark, New Jersey to Houston, Texas on April 26th, 1955. It carried just under 60 containers.

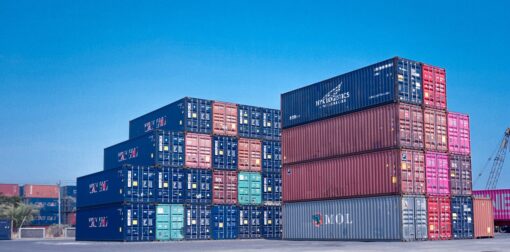

Today, the largest containerships can carry well over 20,000 twenty-foot equivalent units (TEUs). A 20-foot container measures 1 TEU, a 40-foot container measures 2 TEU, meaning that large containerships carry thousands of containers. The technical progress and size growth that containerships have experienced is astonishing! The ability to load more cargo onto one single ship increases efficiency and thus reduces carbon emissions. The popularity of the containership is due to the multi-modal quality of the standard ISO container, which can be loaded onto trucks or transported by rail. With cranes now widely available in major global ports, it is fast and easy to load the containerships.

Modern containerships have their holds (the space where the cargo is stored) divided into bays with cell guides (they are also referred to as cellular ships) in which the crane operators can snugly fit the 20- and 40-foot containers. This enables efficient, speedy loading. 45-foot containers are then stored above the deck. In some ships, the hold is capped with a hatch cover. Container vessels vary by many design element but it is worth mentioning that some may be equipped with cranes. Such ships are referred to as geared (as opposed to gearless ships, which do not feature a crane) or as lift-on/lift-off (LoLo). While this means that these vessels can visit ports that do not offer cranes, those are becoming rarer – and so are LoLo containerships.

Planning Container Loading – A Life-Size Game of TetrisThe correct arrangement of the containers on the ship is called the stowage plan. A container vessel typically calls at several port during its journey: each time the ship berths at port, a certain number of containers will be loaded or unloaded. Correct container arrangement is key to port handing efficiency – imagine having to unload a container and realize that it is located at the bottom of the vessel bay, under a stack of other containers! It is the joint responsibility of the port planner and the chief vessel officer to design an efficient stowage plan. It also contributes to the safety of life at sea. Uneven weight distribution across the vessel can have dramatic consequences, as the vessel can bend. Stacking heavier cargo on top of a container stack can cause it to collapse and threaten the life of the sailors. Refer to our Verified Gross Mass and Safety of Life a Sea (SoLaS) resources to make sure your cargo is transported safely.All modern containerships are equipped with an Automatic Identification System (AIS). This device shares the GPS coordinates of the ship, preventing collisions between vessels and providing visibility in difficult weather condition. It also enables track & trace services